.png) The Gerstein + MADLab 3D printing service provides support for faculty who wish to integrate making into their course instruction. We provide:

The Gerstein + MADLab 3D printing service provides support for faculty who wish to integrate making into their course instruction. We provide:

- hardware safety certification and introductory design software training for students and/or teaching staff

- expert consultations on 3D technologies

- access to 3D printers for hands-on use for assignments

- custom design and of learning objects

- integration of maker competencies into assignments or course outcomes

If you would like to request support for your course, please complete this form. Please note that we request a minimum of one month advance planning for requests, which are accepted on a first-come, first-served basis.

We currently provide subsidized access to 3D printing for students in approved courses. Learning object printing is provided to approved course instructors at a cost of $0.10/gram. Prints are made on a Creality K2 3D printer (service staff access only) in PLA material.

To learn more, please see the examples below or reach out to us at gerstein.3Dprinting@utoronto.ca.

Case: Learning object for anatomy course

Case: Learning object for anatomy course

ANA126: Gross Anatomy for Kinesiology & Physical Education (KPE)

Faculty: Judi Laprade

Enrollment: 320

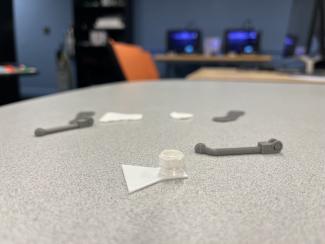

Project: Collaborative design and fabrication of 75 ball and socket joints for in-class student use

Training audience: Teaching assistants

This project for a first-year anatomy class involved adapting a selection of 3D object files to better illustrate the mechanics of ball and socket joints. Several free files from an online object library were selected and adapted in collaboration with faculty support staff to create a specific mechanical function. Through an iterative process of trial and error, the team was able to produce a design that functioned as needed. Lab staff provided a certification workshop for course TAs who printed the bulk of the objects. Project constraints included time available for printing, durability of the materials, accuracy of printing, and the large number of objects required.

Case: Digital humanities assignment

Case: Digital humanities assignment

DHU236H1: Virtual Worlds: Introduction to Spatial Digital Humanities

Faculty: Alexandra Bolintineanu

Enrollment: 40

Project: 3D printing assignment

Training audience: Students

DHU236 students visited the 3D Printing Service at Gerstein and participated in a safety training. This assignment asked students to apply knowledge of the 3D printing process and 3D print an object from an online repository such as Thingiverse. Deliverables included a selfie with their object, a copy of their certification, and a reflection on the process as a user experience.